| C. Scott home | Back to projects page | MAS863 home |

Bits and bytes are becoming more and more interchangable. Napster taught that CDs were just bags of bits --- and that, in fact, the physical CD was considerably less convenient than manipulating the bits. The future will extend this transitive property to more and more of the objects surrounding us. Just as we can hit Google today to find the pure-information answer to whatever trivia is dogging us, a future "object google" will be able to provide us with the physical object we are in need of: a corkscrew, perhaps, or an oddly-shaped screwdriver, or a valentine's day card, or a replacement CD case. Bits defining all these physical objects will be found on Object Napster.

1. Offending the Mouse

1. Offending the MouseOf course, the easy conversion of physical objects to bits will face as much opposition as the Napster's easy conversion of music and bits did. The already-inaccurate term "Intellectual Property" will be the subject of even more confusion as possession of intangible bits enables the creation of real physical property. What patent and copyright laws will govern your home fabricator?

|

|

|

|

|

| The Mouse | goes into | the Box. | Out come | BITS. |

|

|

|

|

|

| The BITS | float onto | the Internet | and come out | the other side |

|

|

|

|

|

| BITS back | in the | Box, | and out pops | the Mouse! |

So what kind of machine can create itself? The first thing that comes to mind is a desktop milling machine such as the Roland MDX-20. But a conventionally constructed milling machine contains ball screws and end mills and other parts which can't be fabricated using a milling machine.

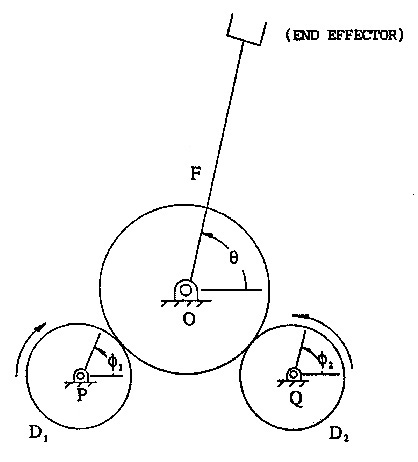

We want a minimal fabrication machine: accuracy for as little cost and complexity as possible. Electrical Discharge Machining is our solution: no moving parts on the discharge head, and the discharge head can be any shape at all. We only need to scan the dischange head in X, Y, and Z:

|

Copyright © 2002 C. Scott Ananian. Verbatim copying and distribution is permitted in any medium, provided this notice is preserved. |

cananian@mit.edu |